|

Eager Space | Videos | All Video Text | Support | Community | About |

|---|

With the recent announcement of more details on Neutron there has been considerable discussion about this new vehicle. I've seen one question come up repeatedly - how will they compete with SpaceX?

I've been planning a Neutron video for a while, but there hasn't been enough technical meat to dive in and do the kind of analysis I like to do. However, the question of competition is a fun one as it revolves more about markets and overall design than specific technical details.

Before I start, in the interest of full disclosure, I own a few thousand dollars of RocketLab stock, so it's fair to say I have a small vested interest in their success...

I'm going to start by talking about competition in general.

If we are thinking of entering a market, we need to know a few things.

Who are the customers?

What are they looking for?

How do they segment?

When we look at cars, we know some people are looking for basic transportation, some are looking for hauling capacity, some are looking for performance, and some for prestige. Those same sorts of concerns apply to launch customers.

If we don't understand the customers, what they care about, and how they differ, we can't understand the market

Second, we need to understand the existing companies that serve that market - the competitors.

What are their strengths?

What are their weaknesses?

How do they differentiate themselves?

Let's look at some details on three companies that you might be familiar with:

McDonald's, Qdoba, and Taco Bell. They are all in the food business, but each is in a slightly different food business.

McDonalds has three things they focus on:

Cheap prices

Speedy customer service

Universality of taste

If you've visited McDonalds, you can tell that this is their focus, or to use a business term, their brand identity.

Qdoba is very different. They focus on:

Freshly prepared, flavorful food made in-house

Menu differentiation

Hospitality

And finally, Taco Bell focuses on:

Cheap prices, high value

Product innovation

Social media engagement

Try to compete with McDonalds on low prices, they will walk over you. Try to out-social-media Taco Bell, their customers will laugh at you.

This leads to a strategy that the business world calls "product differentiation", but I refer to it as "go where they aren't". The goal is to avoid the areas where your competition is strong and focus on the areas where they are weak.

I talked about where SpaceX is strong in my video on competing with SpaceX - see the link - but to summarize, they have 3 major areas of strength.

The first is Dragon - with cargo dragon and crew dragon for ISS, they have contracts with NASA that nobody is going to take away for the rest of the ISS lifetime. And they are selling some non-NASA flights as well.

The second is the national security space launches for the Space Force. NSSL is very hard to qualify for because it requires high reliability and high vehicle performance.

The third is geosynchronous satellite launches. The barriers here are lower because there are no long-term contracts, but big communication satellites inherently require big launchers and you need to compete with both SpaceX and Arianespace.

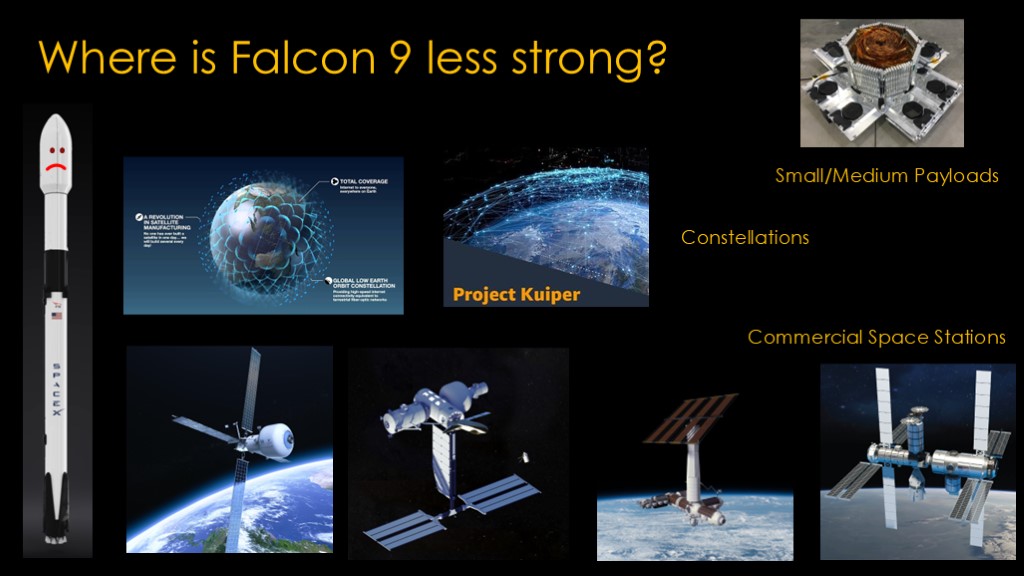

Conversely, if we look where SpaceX is less strong, we find a few opportunities:

On small/medium payloads, they are less exciting. They have flown rideshares, but for many companies the constraints of the rideshare aren't great - they want control over their orbit and their launch date. And most don't need the performance of a Falcon 9.

There are constellations like OneWeb and Project Kuiper that are in direct competition with SpaceX's Starlink and those companies would rather not give their launch business to SpaceX. That is why Neutron is branded as "the mega constellation launcher".

As NASA transitions away from ISS and towards commercial space stations, NASA is going to want multiple suppliers for those stations (the way they do for commercial resupply now), and the pure commercial companies will want the same. This could be a big growth area. There are also opportunities for flying crew.

In addition, there are other NASA payloads; NASA's Launch Services Program is specifically designed to make it attractive for new companies and new launchers.

Why is there an opportunity for competitors?

Falcon 9 was originally designed as a rocket that could garner a commercial resupply contract from NASA and compete with existing launchers on price.

SpaceX also hoped they could use it to develop reusability

After they got Falcon 9 working for reuse they ended up freezing it at what is called block five, and they froze it for a couple of reasons:

The first reason is that NASA wanted a fixed design so that they could understand the safety aspects for commercial crew

the second reason is that SpaceX had decided that they were going to invest their engineering resources on Starship

The important point here is Falcon 9 is not SpaceX's best partially reusable design; it's a modification of an expendable design. They got very good benefit out of it, but if SpaceX did a second partially reusable design, it would be a much better partially reusable rocket.

This is what is known as a market opportunity; as a business you look for competitors that are distracted.

But what about Starship? How will Neutron compete with Starship?

Here are my top 6 reasons why everybody should ignore starship for now.

What starship is changes ever month or so. You cannot come up with a business plan to compete with a company that is a burger house one week and then a seafood restaurant the next.

The launch market doesn't like monopolies. Everybody wants second suppliers. The real question we should be asking is whether there is anybody who can compete with Neutron, because they will become the default second supplier

We have no idea what Starship will cost per flight nor how much it will carry. How could you possible make plans when the price might be $50 million or it might be $10 million.

Starship is arguably the hardest technical thing ever done in space, harder than apollo or shuttle. It is stretching SpaceX to the limit, and it's not clear if/when they will be successful.

SpaceX cares about Mars more than anybody else, and Starship is designed for that environment. Do you think the market needs a second Mars rocket? Or something else?

Do you honestly think you can compete with SpaceX on something like Starship? "Hubris" means "excessive pride or self-confidence". And yes, I'm looking at you, project Jarvis.

Why Blue Origin keeps taking their current projects that aren't progressing well and making them harder baffles me.

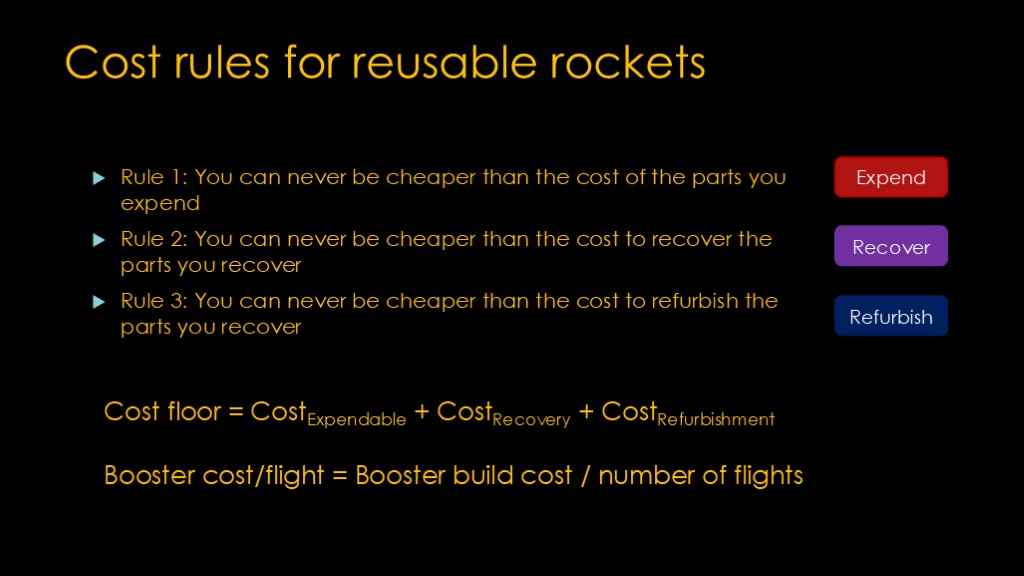

Let's talk about the cost structure for reusable rockets. I've come up with three cost rules:

The first rule is that you can never be cheaper than the cost of the parts you expend. if you have a second stage and it's expendable your cost can never go lower than the cost of your second stage

The second rule is that you can never be cheaper than your per-flight recovery costs. However you recover the reusable parts, you need to pay that cost every flight.

The third rule is that you can never be cheaper than the cost to refurbish the parts you recover so that you can fly them again.

We can write that as an equation; the cost floor for a launch is the cost of the expendable parts plus the cost of the recovery plus the cost of refurbishment.

On the other hand, the cost of the reusable booster is spread over the number of flights it completes, so you can reduce its cost simply by flying it more.

This means that the ultimate cost per flight is determined by the cost floor, not by the cost of the booster.

What are the main drivers for the Falcon 9 cost floor?

There is the cost to make the second stage, which is expended on every flight

There is the cost to recover the booster and fairings. This requires drone ships, support ships, dock space, etc. , which have significant fixed and incremental costs.

There is the cost to refurbish the booster engines, which use a propellant mix (RP-1 and liquid oxygen) that deposits soot in some parts of the motor.

These are significant costs that impact the cost floor, and therefore the overall cost of the system.

A Falcon 9 booster likely costs $30 million or so, and if it flies 10 times, the capital cost of that booster is $3 million per flight

The flight costs are therefore dominated by the cost floor, which is likely three to four times that amount.

Before discussing the specifics of Neutron, a brief digression on aerospace materials will be useful

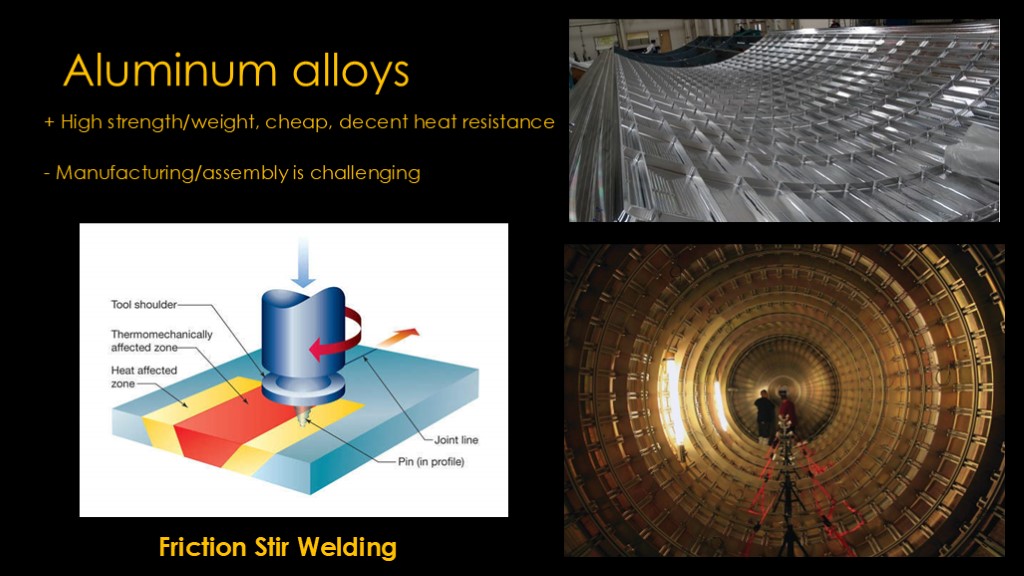

Aluminum alloys have been used for quite some time in rockets. They have a high strength to weight ratio, decent heat resistance, but manufacturing and assembling them is challenging.

The upper right shows a ULA rocket tank using what is known as an "orthogrid" design. It started as a big flat slab of aluminum and the inside of each rectangle was machined away, and then it was bent into the appropriate curve.

The lower right shows the inside of a Falcon 9 tank; SpaceX uses sheet aluminum that then has strengthening stringers attached to it. Both of these methods are slow and expensive.

To weld together aluminum tanks, a technique known as friction stir welding is often used, where a spinning tool with a pin is applied to the seam with enough force to melt the two sides of the seam and they then cool and are welded together. This produces very strong welds but the process is slow and the equipment is expensive.

Stainless steel has very high strength, is cheap, has great heat resistance, and is easy to machine and weld. It is unfortunately quite heavy.

The right picture shows the inside of a centaur stage during manufacturing, and this stage has been built for more than 50 years, dating back to the 1960s.

The left picture shows part of the SpaceX's Starship vehicle being welded out in the open air.

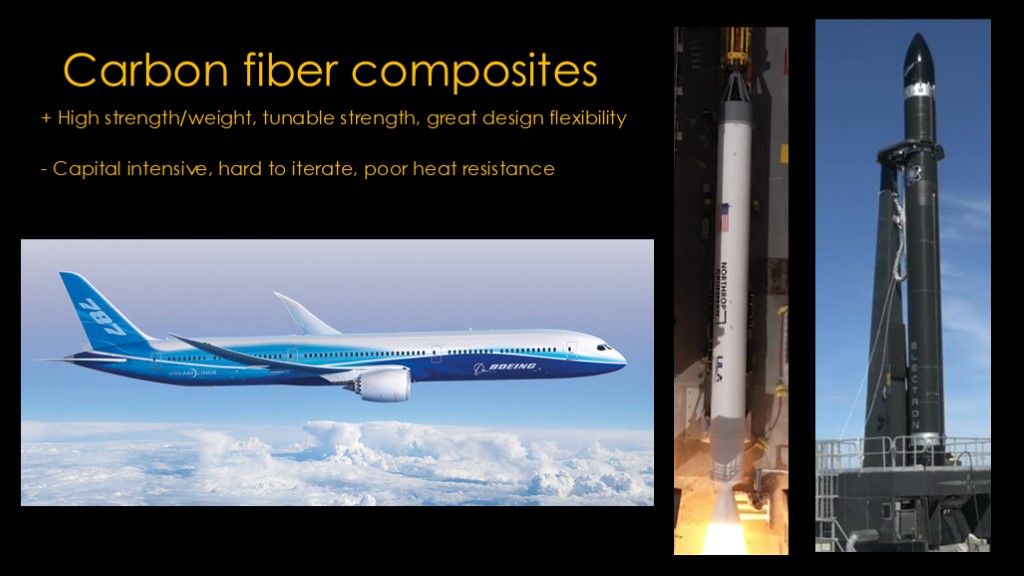

A third option is carbon fiber composites.

They have great strength/weight ratio - perhaps 20-40% lighter than the alternatives - and this can be easily tuned to meet the expected loads. They also allow great design flexibility.

However, they require a significant amount of equipment to fabricate, changes are harder to make, and they have poor heat resistance.

They are very widely used in aviation - the Boeing 787 is about 50% carbon fiber by weight, and Boeing has used the design flexibility to produce a very distinctive and efficient upswept wing.

In rockets, they have mostly been used as simple tubes, with some solid rocket motor casings and of course RocketLab's Electron rocket.

Bicycles provide a good example of what can be done with carbon fiber.

This bicycle from the 1980s; it uses steel tubes of various diameters, that are then joined together with brazed connections.

The bicycle on the right is one of the first carbon fiber bicycles. Note that it looks very much like the steel bicycle; the big difference is that it is using tubes made of carbon fiber, but it does not take advantage of any of the design options that carbon fiber provides. This is exactly the way that carbon fiber has been applied to rockets; a lighter material for big tubes, but still big tubes.

This is the bike that I currently ride. Note that very few of the frame sections are tubular and most of them taper. The frame is designed to provide strength where strength is needed and compliance/flexibility where that is needed. Not only is the size and shape of the tubes designed, the alignment of the carbon fiber in each section is controlled to be strong enough and yet very light.

The bike on the right is a time-trail bike, designed to be as aerodynamic as possible, and therefore as fast as possible. The designers have really used the flexibility of carbon fiber to produce a bicycle that is optimized to go fast.

That is the sort of design that RocketLab will be applying to Neutron; it won't just be a "better and lighter tube" design, it will be a "use all the advantages that carbon fiber allows" design.

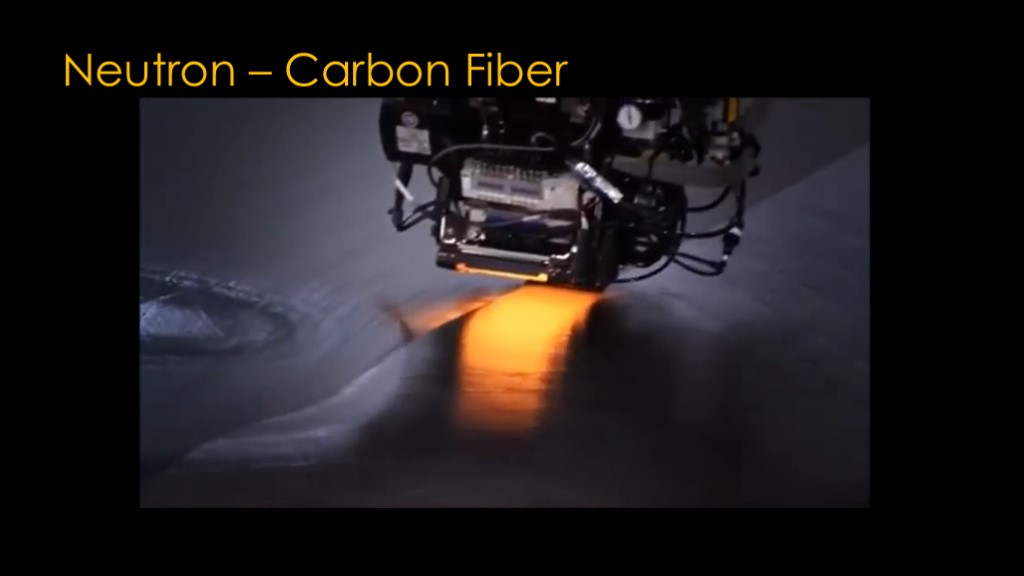

To build the Neutron, RocketLab will use what is known as "automated fiber placement" - it essentially uses a robot that places the carbon fiber on top of a mold, building up both the appropriate thickness of carbon fiber and the appropriate fiber alignment.

This video shows Lockheed Martin using automated fiber placement to build a small airframe. The Neutron approach will be similar but scaled up for the size of Neutron.

RocketLab has made a number of design choices to make Neutron as cheap as possible. Before we look at them, I want to review the three design rules, expressed slightly differently:

Minimize the cost of the parts that you throw away

Minimize the cost to recover the parts that you reuse

Minimize the cost to refurbish the parts that you reuse

Do that, and you will minimize the per-launch cost

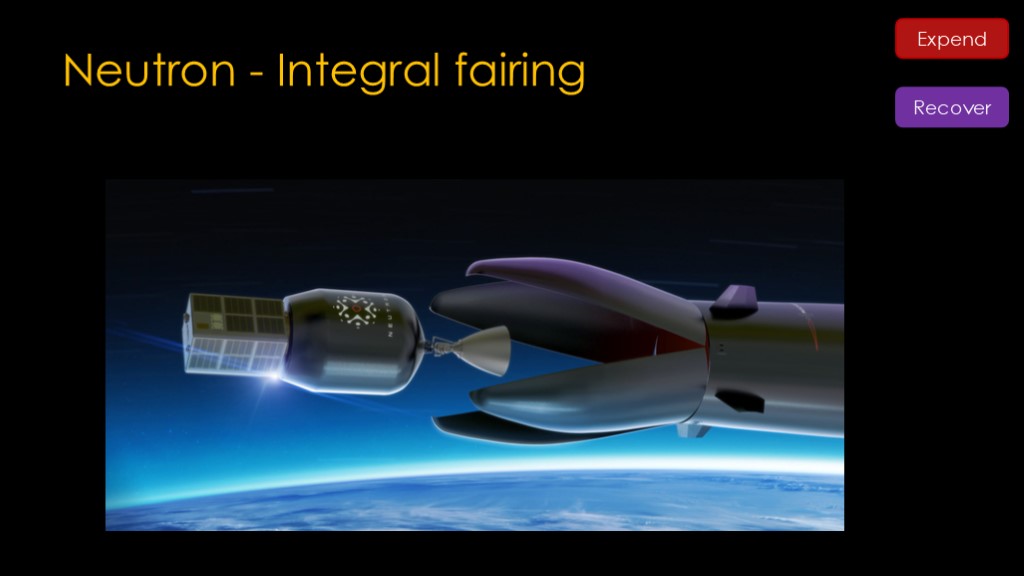

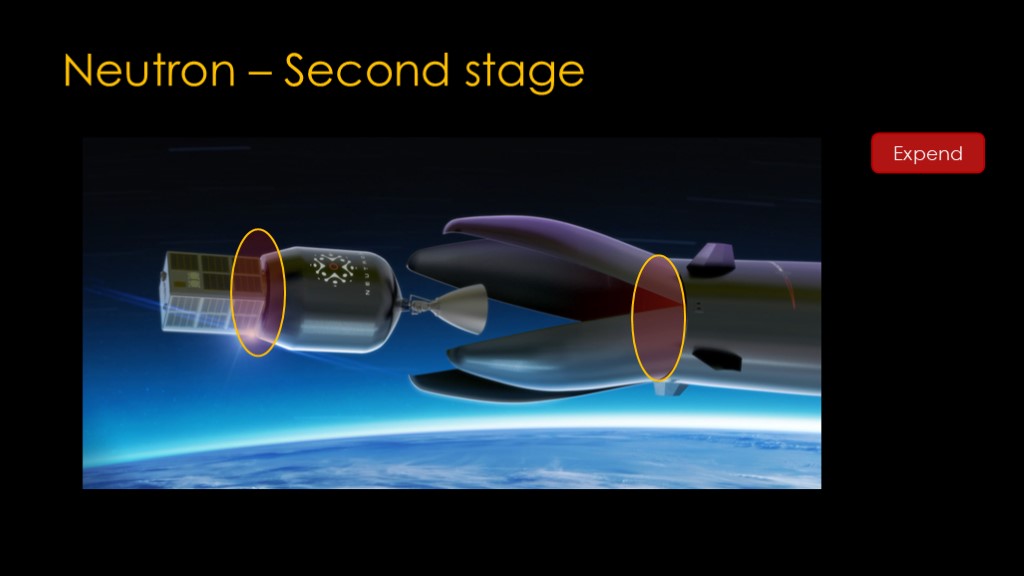

Neutron features a fairing that is integrated into the booster. This means that fairing recovery is automatic - the fairing ends up wherever the booster ends up, and there is no refurbishment required.

There is a support structure between the second stage and payload, and this support structure will attach to the booster at the base of the fairing petals.

This approach moves the mass of the structure that supports the second stage and payload from the expendable second stage into the reusable booster, and it also moves the fairing mass to protect the payload from aerodynamic forces to the booster as well.

This allows the second stage to be much lighter, cheaper, and better performing.

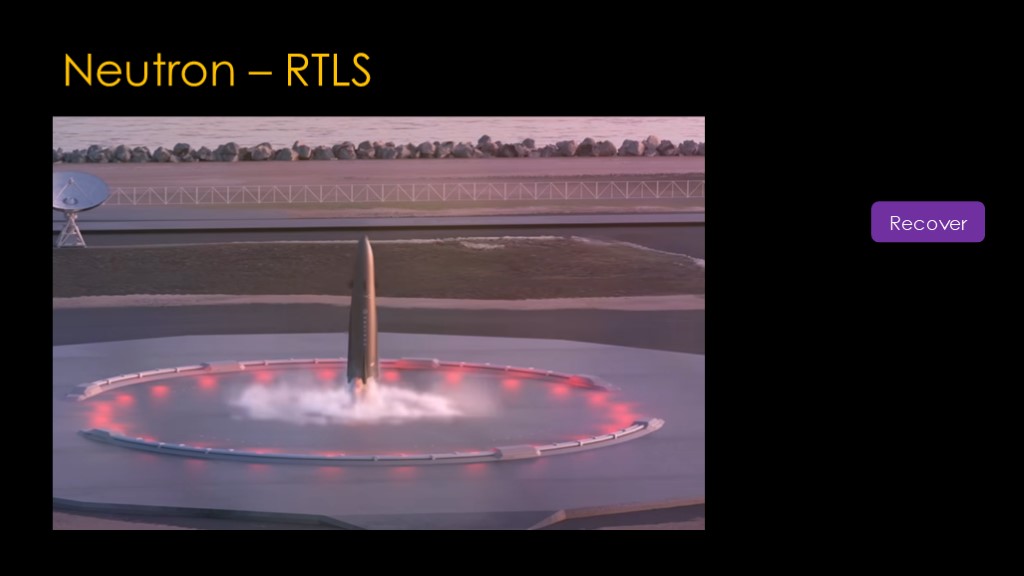

The neutron will always return to land at the launch site. That eliminates the expense and complexity of recovery at sea - landing platforms, support ships, docks, cranes, and transport vehicles.

It also reduces the time it takes to get a booster ready to fly the next payload, as it would normally take days for a ship to return, and this may allow fewer boosters to fly the same number of payloads.

Landing on a drone ship downrange is a *performance* optimization. Returning to the launch site is a *cost* optimization, and RocketLab has chosen the cost optimization over the performance optimization.

This is exactly the choice that SpaceX has made with Starship and Super Heavy.

Neutron uses integral carbon fiber landing legs that are part of the airframe and will be lighter and require less refurbishment than the folding legs used on the Falcon 9.

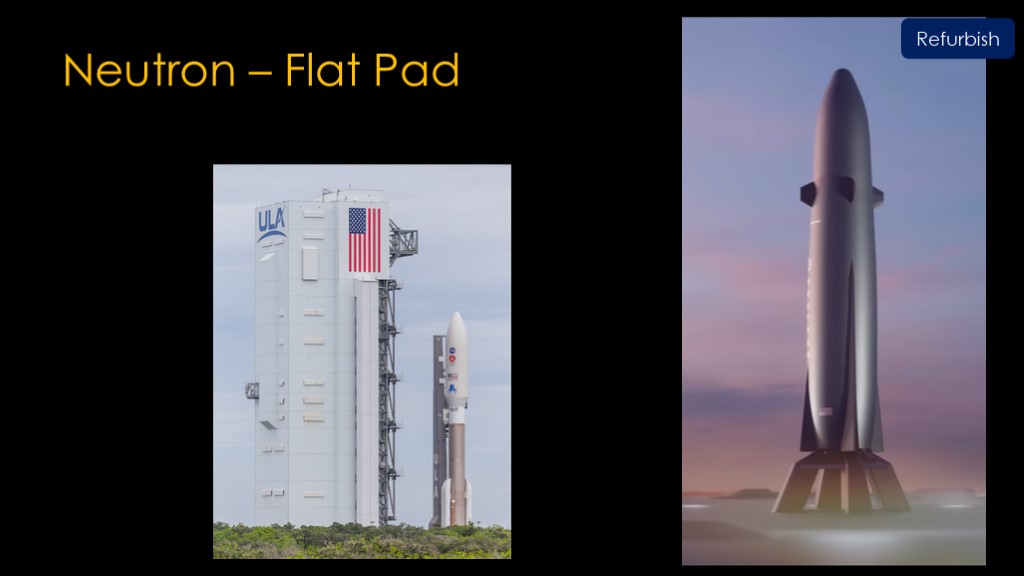

Something is missing from the Neutron launch site - there is no launch tower, merely a short launch platform. Both the booster and second stage will be fueled through the booster. This will limit the amount of pad maintenance required after a launch.

It's not clear yet how Neutron gets on the launch platform, nor how the second stage and payload are placed inside the booster. One option would be the approach that ULA uses on the Atlas V, where the rocket is assembled and the payload encapsulated inside a building and then rolled out to the pad.

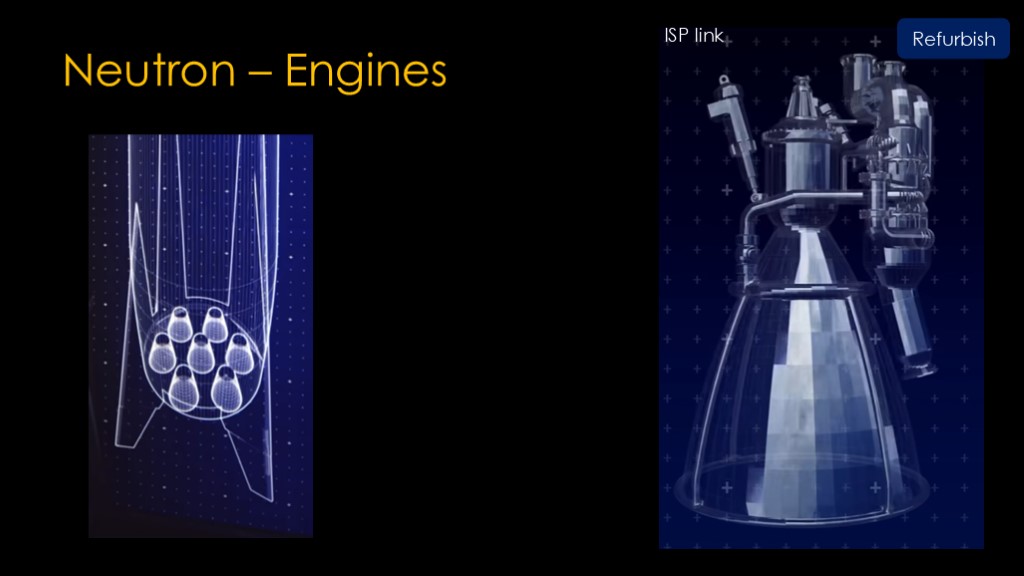

Neutron takes a page from the Falcon 9 design when it comes to engines.

It uses 7 engines in the first stage, as that is enough to do propulsive landing. The new Archimedes engine uses a tried-and-true gas generator approach, just like the SpaceX Merlin used on the Falcon 9, but it will be burning liquid methane and liquid oxygen (known as methalox) instead of RP-1 and liquid oxygen (kerolox). Liquid methane burns much cleaner and therefore reduces the amount of engine refurbishment considerably.

It is reportedly a lightly stressed engine, which will make development quicker and easier and means less refurbishment. It has an ISP (add link) of 320, which is probably the sea-level engine in vacuum. That's better than the 311 that the Merlin gets, but much less than the 348 that the Raptor gets.

The best comparison of this engine is probably the Merlin 1A that SpaceX developed for the Falcon 1. A light, simple, reliable engine that can be easily reused.

The second stage will use a vacuum variant of the same engine.

From the details that have been disclosed, Neutron will be an optimized version of the Falcon 9; it will waste less money on the second stage and fairings, spend far less money on recovery and refurbishment, and it will benefit from both SpaceX's experience with Falcon 9 and RocketLab's experience with carbon fiber and Electron.

The answer to the question of whether Neutron is Falcon 9 Mark II is "Yes", and that's why Neutron will win in the market...